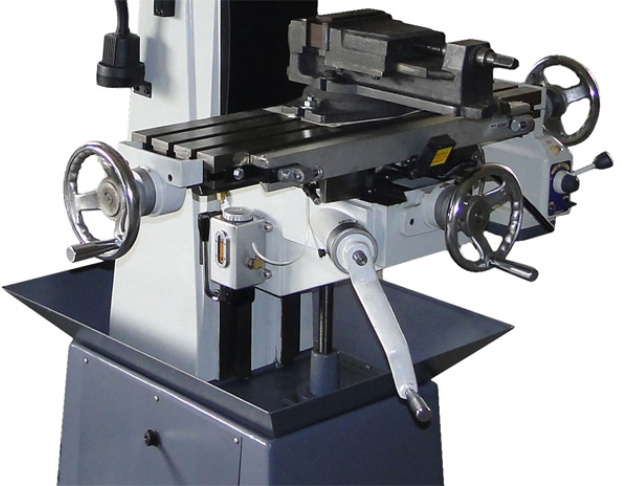

YES-830-A3 8" x 30" Turret Milling Machine

l This 8" x 30" Vertical Milling Machine includes all the same features as its 6" x 26" little brother, but is constructed with a heavy, one-piece casting for even greater rigidity and an extra 300 pounds of mass.

l It also accommodates up to a 14" swing and 20" between table and spindle. Features a built-in drain and cabinet designed to accept aftermarket coolant systems, making it readily upgradable. Available with or without longitudinal power feed.

Milling Machine Features

Basically the milling machines are divided into two types first is horizontal milling machine and second one is vertical milling machine. They are further classified as knee-type, ram-type, manufacturing or bed type and planer-type milling machine.

- Adjustable table stops for accurate stops for cuts and repeatability

- Head tilts to 90° both ways. 360° rotation on horizontal surface

- Scrapping technology X,Y & Z. PS : The scrap technology is considered as the fundamental of the accuracy of precision machine tools.

- Hardened & ground column and knee slideways.

- Solid cast iron construction throughout.

- Spindle stop with micro-adjustable setting.

- Chrome plated precision ground quill.

- Heavy-duty saddle supports full width of table.

- High precision ground vertical and cross ways.

- Class 7 spindle bearings.

- Lower noise and convenient operation.

- Table locks for high rigidity.

- Adjustable travel stops on X & Y.

- Fold up safety handles.

- Dovetail ways X,Y & X.

- Adjustable gibs.

- Fine down feed on quill on table.

- Standard:Working Linght、Drawbar.

Milling Machine optional accessories

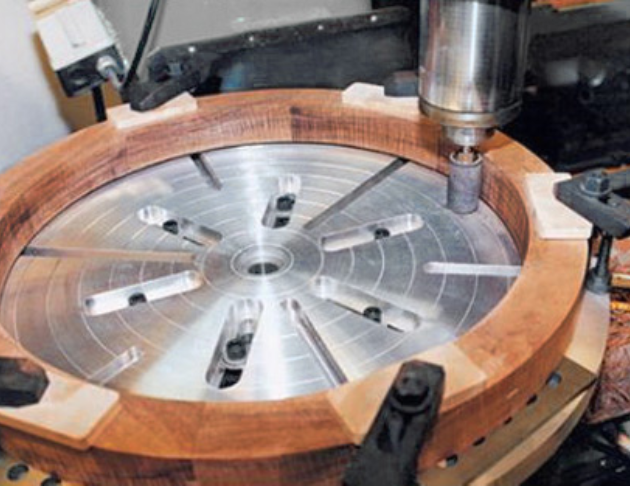

There are multipurpose optional accessories for milling machine, which will increase the working efficiency and add the possibilities for more cutting methods.

Chip Tray

Power Feed

-wwgcaa.jpg)

Coolant System

-4f7h0h.jpg)

Quartz Lamp

-1lps8h.jpg)

2 axis DRO System

-p8dmwf.jpg)

3 axis DRO System

-sx9sqr.jpg)

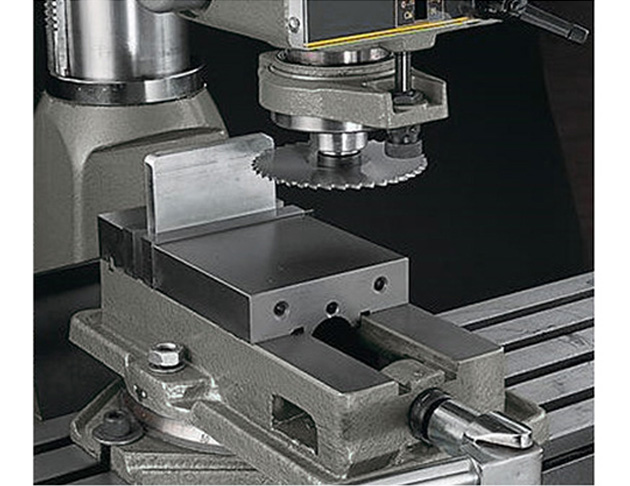

Milling Vise

Clamping Kits

Milling Chuck

- Adjustable table stops for accurate stops for cuts and repeatability

- Head tilts to 90° both ways. 360° rotation on horizontal surface

- Scrapping technology X,Y & Z. PS : The scrap technology is considered as the fundamental of the accuracy of precision machine tools.

- Hardened & ground column and knee slideways.

- Solid cast iron construction throughout.

- Spindle stop with micro-adjustable setting.

- Chrome plated precision ground quill.

- Heavy-duty saddle supports full width of table.

- High precision ground vertical and cross ways.

- Class 7 spindle bearings.

- Lower noise and convenient operation.

- Table locks for high rigidity.

- Adjustable travel stops on X & Y.

- Fold up safety handles.

- Dovetail ways X,Y & X.

- Adjustable gibs.

- Fine down feed on quill on table.

- Standard:Working Linght、Drawbar.

左右尚有資訊

左右尚有資訊| Model No. | YES-830-A3 |

| Spindle Taper | MT3 or R8 or NT30 or NT40 |

| Spindle Max. Travel | 5" (127 mm) |

| Spindle Feeding | Manual / Auto feeding by 3 steps 0.04 , 0.08, 0.15 |

| Spindle Speeds | 90~2780 RPM (8 speeds) |

| Distance, Spindle To Table Surface (Z) | 2.5"~19" (65~480 mm) |

| Size Of Working Table | 8" x 30" (205 x 760mm) |

| T-Slots Size (Number) | 3/8" (3 slots) |

| Longitudinal Table Travel (X) | 18½" (470 mm) |

| Cross Table Travel (Y) | 8" (200 mm) |

| Vertical Travel Of Table (Z) | 18.1" (460 mm) |

| Motor | 2HP / 3PH |

| Swing | 6.5"~18" (165~457 mm) |

| Lead Screw for Drill Chuck | 1"*8 TPI or 3mm Pitch |

| Vertical Head Tilt Angle (R&L) | 90° |

| Ram Swiveling Angle | 360° |

| Net Weight | 470 KGS |

| Gross Weight | 520 KGS |

- Adjustable table stops for accurate stops for cuts and repeatability

- Head tilts to 90° both ways. 360° rotation on horizontal surface

- Scrapping technology X,Y & Z. PS : The scrap technology is considered as the fundamental of the accuracy of precision machine tools.

- Hardened & ground column and knee slideways.

- Solid cast iron construction throughout.

- Spindle stop with micro-adjustable setting.

- Chrome plated precision ground quill.

- Heavy-duty saddle supports full width of table.

- High precision ground vertical and cross ways.

- Class 7 spindle bearings.

- Lower noise and convenient operation.

- Table locks for high rigidity.

- Adjustable travel stops on X & Y.

- Fold up safety handles.

- Dovetail ways X,Y & X.

- Adjustable gibs.

- Fine down feed on quill on table.

- Standard:Working Linght、Drawbar.

左右尚有資訊

左右尚有資訊| Model No. | YES-830-A3 |

| Spindle Taper | MT3 or R8 or NT30 or NT40 |

| Spindle Max. Travel | 5" (127 mm) |

| Spindle Feeding | Manual / Auto feeding by 3 steps 0.04 , 0.08, 0.15 |

| Spindle Speeds | 90~2780 RPM (8 speeds) |

| Distance, Spindle To Table Surface (Z) | 2.5"~19" (65~480 mm) |

| Size Of Working Table | 8" x 30" (205 x 760mm) |

| T-Slots Size (Number) | 3/8" (3 slots) |

| Longitudinal Table Travel (X) | 18½" (470 mm) |

| Cross Table Travel (Y) | 8" (200 mm) |

| Vertical Travel Of Table (Z) | 18.1" (460 mm) |

| Motor | 2HP / 3PH |

| Swing | 6.5"~18" (165~457 mm) |

| Lead Screw for Drill Chuck | 1"*8 TPI or 3mm Pitch |

| Vertical Head Tilt Angle (R&L) | 90° |

| Ram Swiveling Angle | 360° |

| Net Weight | 470 KGS |

| Gross Weight | 520 KGS |

256 bit SSL Encryption

256 bit SSL Encryption